chinaPEEK@chinaPEEK.com

Mobile phone

+86-519-86228823

Clear records

history record

Products

Tubing system

High fuel costs and environmental protection become a major challenge.

Aerospace Industry

It is imperative to reduce weight and improve fuel efficiency.

High fuel costs and environmental protection become a major challenge.

Reduced production time and faster assembly are critical.

Aircraft makers must keep pace with high demand.

Longer life and reliability needs.

Minimize aircraft maintenance while ensuring safety.

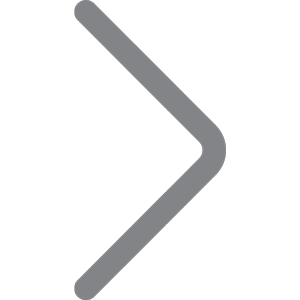

Among the aircraft materials, titanium alloy accounts for 15% and aluminum alloy accounts for 20%.The same size and volume, different material test blocks,there is a huge difference in density.

PEEK Enables Lightweight Alternative Metal Aerospace Materials

The use of lightweight PEEK material can not only improve fuel efficiency and meet environmental requirements, but also make assembly faster and more reliable, and lower operating and manufacturing costs. This is the trend in aerospace design.

Aerospace engineers need strong, lightweight materials that simplify part design, reduce system cost, and provide durability in harsh environments. JUNHUA PEEK creates value for customers through high-performance PEEK polymer solutions and is a domestic leader in this field. The first China manufacture of PEEK to pass the aerospace certificate AS9100D.

JUNHUA PEEK focuses on PEEK, PI and other high-performance plastic raw materials and products. It can not only provide customers with PEEK material solutions but also provide suggestions and solutions in the design of new product applications.

Molded, granulated, and sprayed powders are available. We can provide pure particles and modified particles for injection molding, extrusion, and other processes. JUNHUA PEEK can provide differentiated PEEK products to help customers solve the toughest challenges.

PEEK5600 Series Advantages

PEEK5600G:Excellent processability and toughness, suitable for thin-walled products.

PEEK5600GF30:High strength and high modulus, suitable for pressure vessels or occasions with high-pressure requirements.

PEEK5600CF30:Carbon fiber reinforced PEEK with excellent mechanical properties.

PEEK5600LF30:With excellent wear resistance, it is suitable for high-speed, high-load applications.

Small Specific:Gravity Replacing titanium alloy (4.5g/cm3) and aluminum alloy (4.5g/cm3) to achieve lightweight.

High Wear Resistance:The melting point is 343°C, long-term use at 260°C, the thermal deformation temperature of the composite material is about 330°C and higher temperature resistance.

High strength:The mechanical properties of PEEK modified by chopped fibers are slightly lower than those of aluminum alloys.

Corrosion resistance:It has corrosion resistance to most organic solvents such as acids and alkalis. It is corroded by halogens and strong acids at high temperatures and is soluble in concentrated sulfuric acid at room temperature.

Thermoplastic material:Fatigue resistance and impact resistance are significantly better than thermoset materials, have a longer life, are environmentally friendly, and are recyclable.

Material stability:It better reflects the characteristics of low gas release in outer space and a vacuum coating environment.

Wearing resistance:High hardness and low friction coefficient.

Stable dimension:PEEK reduces the coefficient of expansion, thereby radically reducing the risk of swelling.

CF-PEEK Composite

Advanced composite materials play important roles in the aerospace field. CF/PEEK composite materials have extremely high-heat resistance (heat deformation temperature up to 310℃), corrosion resistance, friction resistance, and other advantages. It can effectively reduce the weight of aircraft, launch vehicles, missiles, and satellites, increased payload and range, and reduced cost.

The composite material of CF/PEEK has very high mechanical properties, meanwhile has higher impact resistance than traditional thermoset composites, which can be fabricated for aircraft landing gear skin components, while reducing the weight of the aircraft.

PEEK Application

PEEK Parts Used in Aerospace Industry

Civil aircraft application

Airbus A340/A380 wing leading edges, and aircraft interior parts, including seat frames, brackets, beams, and intake ducts are also applied with PPS composites. PEEK composite materials are used for doors, windows, link corner pieces, etc. The application of main mechanisms, such as fuselage panels, wing boxes, and stringers, is still in the experimental stage.

Military aircraft application

PEEK prepregs material has been used in fully automatic tails, fuselage belly panels, fuselage skins, nose landing gear doors, main landing gear door, wing panel, horizontal stabilizer leading edge, etc.

As wave-transmitting materials PEEK, PEKK, PES, and other resins have good performance in radar transmission and power-saving projection. When radar waves are thrown into these resin-based composite materials, it is not easy to form creeping electromagnetic waves. The unidirectionally reinforced grade of carbon fiber and PEEK multifilament yarn is suitable for making helicopter rotors and missile casings.

Thanks letter

Material: CF/PEEK Composite

On May 5, 2020, the first flight of the Long March 5B carrier rocket was a complete success, and the first mission of my country's space station stage mission was completed. This success lays a solid foundation for the full realization of the third-step development strategy of my country's manned space project.

The PEEK composite material developed by JUNHUA PEEK has realized the highly reliable zero-position locking performance of the booster servo mechanism and contributed its meager strength to the successful launch.

PEEK Parts and Types of Its Modification

Clamp and stand-offs

Material: PEEK5600GF30

The low hygroscopicity of the PEEK polymer material ensures that the tie is dimensionally stable so that it does not swell and not damage the insulation of the wire.

Radar radome

Material: PEEK5600G

Compared to other radome materials, PEEK materials are more electrically stable in extreme temperature environments.

Tubing system

Material: PEEK5600G

Aircraft fuel pump hydraulic power supply protection for water/wastewater piping systems, environmental control systems, and cable systems.

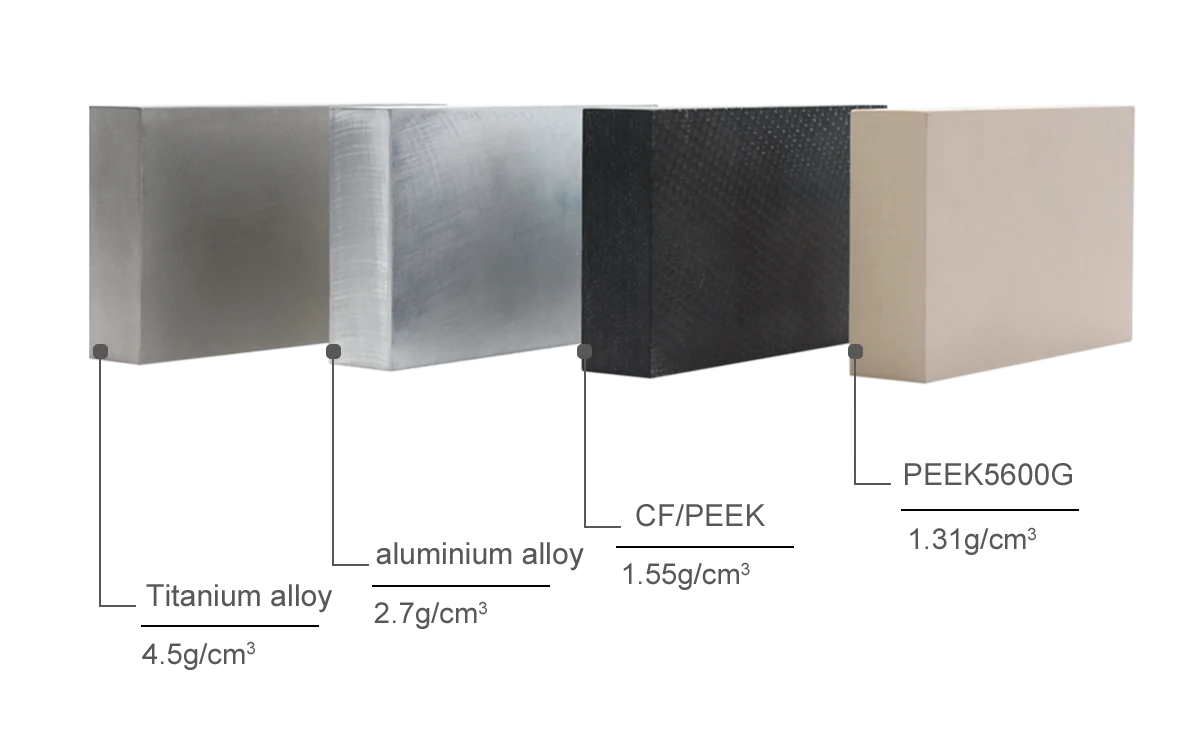

Insulating jacket

Material: PEEK monofilament

PEEK monofilament can be used to weave heat-resistant filter weave, fuel filters, artificial clamps, high-temperature insulation sheaths on aircraft, etc.

Engine control housing

Material: PEEK5600CF30

Engine control housing, bolts, nuts, inserts, brackets, etc. made of PEEK materials are resistant to high temperature, and corrosion and are lightweight.

Shell cover

Material: PEEK5600GF30

30% glass fiber reinforced PEEK has good pressure resistance and heat insulation properties, and low gas release.