chinaPEEK@chinaPEEK.com

Mobile phone

+86-519-86228823

Clear records

history record

Products

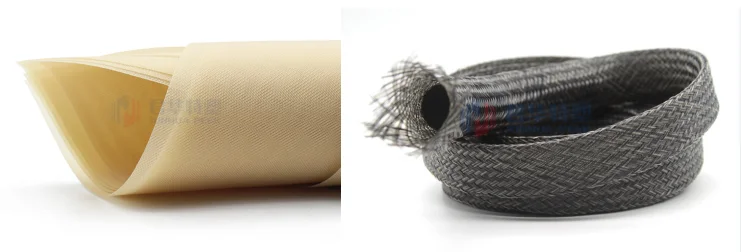

PEEK filament(carbon fiber)

The first Chinese manufacturer to develop PEEK filament

Polymerization of PEEK | Compounding| Extrusion | Pressing | Die casting | Treatment

PEEK thread

Polyetheretherketone, or PEEK, is one of the most efficient polymer plastics. This high-purity, high-temperature polymer has excellent dielectric properties, a very low coefficient of friction and can withstand the most severe physical and mechanical stress.

JUNHUA ChinaPEEK manufactures PEEK tubing by extrusion,precision PEEK tubing are mainly used in HPLC and medical industry, all PEEK tubing is extruded in JUNHUA’s GMP standard clean room. JUNHUA ChinaPEEK can ensure OD & ID ±0.03mm tolerance in our standard extruded tubing. Colored PEEK tubing, color stripped PEEK tubing and special modified PEEK tubing is also available.

Certificate & Compliance

Main Advantages of PEEK Filament

● Good wearing performance with or without load

● High service temperature (long term 260℃)

● Good mechanical strength

● Good chemical resistance & Hydrosis resistance

● FDA approved

PEEK Filament Application Industries

PEEK Filament Typical Data

| PEEK5600G | PEEK5600CF30 | PEEK5600GF30 | PEEK5600LF30 | |||

| Element | Standard | Units | Data | Data | Data | Data |

| Color | - | - | Natural | Black | Natural | Black |

| Density | ISO 1138 | g/cm3 | 1.3±0.01 | 1.4±0.03 | 1.5±0.01 | 1.44±0.05 |

| Water absorption(25℃.24Hrs) | ISO 62 | - | 0.05% | 0.05% | 0.05% | 0.05% |

| Melting temperature | ISO 11357 | ℃ | 343 | 343 | 343 | 343 |

| Distortion temperature | ISO 75-1/-2 | ℃ | 163 | 315 | 315 | 315 |

| Continuous operation Temperature | UL 74685 | ℃ | 260 | 260 | 260 | 260 |

| Thermal expansion coefficient | ASTM D696 | /K | 4.7*10-6 | 1.5*10-6 | 2.2*10-6 | 2.4*10-6 |

| Tensile strength (23℃) | ISO 527 | MPa | 100 | 125 | 110 | 70 |

| Elastic modulus(23℃) | ISO 527 | GPa | 3.8 | 9.3 | 7.9 | 4 |

| Tensile Elongation (23℃) | ISO 527 | - | 27% | 2.50% | 3.50% | 2.50% |

| Bending Strength (23℃) | ISO 178 | MPa | 163 | 271 | 214 | 100 |

| Flexural modulus (23℃) | ISO 178 | GPa | 3.5 | 9.1 | 7.5 | 4 |

| Impact force(23℃) | ISO 604 | MPa | 123 | 196 | 142 | 135 |

| Izod impact strength (unnotched) | ISO 180/U | kJ/m2 | Endless | 38 | 41 | 26 |

| Poisson's ratio | ISO 527-2 | - | 0.4 | 0.35 | 0.35 | 0.35 |

| Rockwell hardness | GB3398.2 | - | 118 | 123 | 122 | 120 |

| Flammability | UL 94 (1.5 mm) | - | V-0 | V-0 | V-0 | V-0 |

| Dielectric strength | IEC 60243-1 | KV/mm | 18 | - | 17 | - |

| Dielectric constant | IEC 60250 | - | 3.2 | - | 3.4 | - |

| Thermal conductivity | ISO 22007 | W/(m·K) | 0.28 | 0.95 | 0.31 | 0.86 |

| Surface resistance | IEC 90093 | Ω | 10^15 | 10^5 | 10^15 | 10^5 |

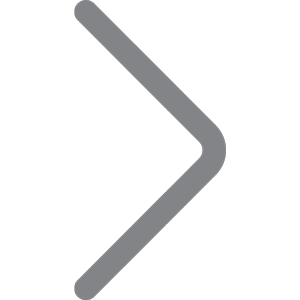

PEEK sheet program

| Diameter(mm) | Tolerance(mm) |

| 0.2 | ±0.03 |

| 0.5 | ±0.03 |

| 1.5 | ±0.03 |

| 1.75 | ±0.03 |

| 1.95 | ±0.03 |